Preventive maintenance program (PM) is a must for businesses that rely on heavy machines and cumbersome equipment, especially if they operate in challenging environments that may involve strict safety rules.

How to create a preventive maintenance program? What are the benefits of it? What is a 10% rule and why do you need to follow it?

1. What is a preventive maintenance program?

A preventive maintenance program refers to a preemptive method of equipment maintenance that involves the identification and resolution of potential issues before they escalate into major problems. Sometimes, the rush of daily operations makes it difficult to spot the faults and thus, they tend to be overlooked and eventually evolve into major issues. When malfunctions are identified in advance, it helps to eliminate costly repairs or replacement of equipment. As a result, the machines’ lifetime increases (as well as their reliability), and their users feel safer and more confident in their tools.

2. Types of preventive maintenance programs

Different types of preventive maintenance programs allow companies to prioritize particular needs and adjust to the requirement that their equipment has. The most common types of PM programs are:

- Time-based Maintenance: This type of preventive maintenance involves performing maintenance tasks at fixed intervals or time-based schedules.

- Usage-based Maintenance: this approach involves performing maintenance tasks based on the actual usage or meter readings of the equipment.

- Condition-based Maintenance: This type of preventive maintenance relies on monitoring and assessing the condition of the equipment or system in real-time.

- Predictive Maintenance: This approach utilizes advanced data analysis techniques and technologies, such as machine learning and predictive modeling, to forecast equipment failures or degradation.

- Reliability-centered Maintenance (RCM): RCM is a comprehensive approach that focuses on critical equipment and aims to optimize maintenance strategies based on the equipment’s function, failure modes, and consequences.

- Risk-based Maintenance: This type of maintenance program prioritizes maintenance activities based on the level of risk associated with equipment failure.

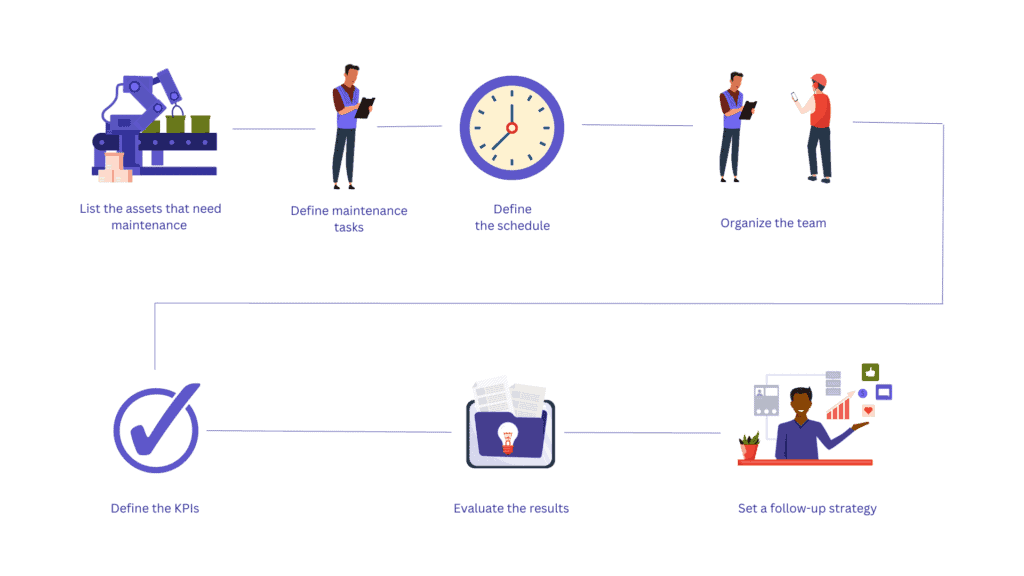

3. How to create a preventive maintenance program?

1. List the equipment for maintenance

What type of machines do you work with? Identify the models, how long they have been in exploitation, are they your own assets or are you leasing them? You must include the assets that require regular maintenance activities.

2. Define maintenance tasks

Maintenance tasks depend on the equipment you use. Some general activities that can be performed are the following:

- inspection

- cleaning

- lubrication

- calibration

- testing

- software updates

- upgrade of the outdated parts

It is essential to remember that not all maintenance activities are created equal and it is better to organize them according to priority (low, medium, high) when scheduling them.

3. Define the schedule

The time to launch your preventive maintenance program depends on a variety of factors: the number of assets to check, the manufacturer’s recommendations, equipment usage, the number of technicians that are available for maintenance activities, operating conditions, and so on.

Modern tools allow scheduling maintenance activities directly in your calendar, which makes it easy to notify the members of the team about upcoming tasks or any changes in their organization.

4. Organize the team

Technicians’ insights should not be overlooked as they are the ones who work with the equipment on a daily basis. Therefore, their feedback can significantly influence the preventive maintenance program. Identify their availability and assign them to the assets that need to be checked in accordance with their expertise.

5. Define the KPIs that need to be tracked

The objective of the KPIs is to identify whether the preventive maintenance program was successful or not. This subject can also be brainstormed with the technicians.

The initial KPIs are:

- Equipment uptime: The amount of time that equipment is available and remains operational, compared to its total scheduled operating time.

- Mean time between failures (MTBF): The average length of time that equipment operates between failures.

- Mean time to repair (MTTR): The average time it takes to repair equipment after a failure occurs.

- Maintenance cost: The cost of maintaining equipment, including labor, parts, and other expenses, compared to the equipment’s value or revenue generated.

- Preventive maintenance compliance: The percentage of scheduled preventive maintenance tasks that are completed on time.

- Work order backlog: The number of maintenance work orders that are awaiting completion, compared to the total number of work orders.

- Overall equipment effectiveness (OEE): A measure of the equipment’s overall performance, taking into account availability, performance, and quality.

6. Evaluate the results

Based on the documented results, you can conclude the state of the assets and the areas of improvement.

7. Set a follow-up strategy

Use the data to forecast the next steps in accordance with the obtained results as well as appropriate tools to store your data and schedule the next interventions.

4. Components of a successful preventive maintenance program

A preventive maintenance program is a complex process that is based on the following key components that can make it successful:

- Use of technology: field service management tools facilitate maintenance activity as technicians can plan out their departure on site, keep, track of the things they need to fix, and provide end-of-the-maintenance-program feedback.

- Clear communication with your team members and collaboration: use the tools that can ensure sharing of large media attachments, streamline the collaboration, and keep your team members notified about any changes that occur in the maintenance cycle. Collaborators should be able to access the created tickets/work orders and work within them. A remote visual assistance solution comes in handy when it comes to addressing these challenges. Even in an environment with a bad connection, remote visual assistance tools allow sharing files in high resolution when a technician is on-site and his team members are in the office.

- Training and education: all the data about the equipment, the maintenance that has been conducted, the comments of the team members, etc. can be converted into learning materials such as guides and tutorials. Modern solutions make knowledge management easier and as a result, boost employees’ confidence and autonomy. They allow storing media files with no limit in size for as long as needed avoiding the risk of losing important data.

- Continuous improvement: generated data can be transferred to R&D departments for product development and improvement.

5. Best practices for maintaining a preventive maintenance program

What are the strategies and tools that can help you organize preventive maintenance programs to their most efficiency? Here are some of them:

5.1. Follow the 10% rule

The golden 10% rule for preventive maintenance programs states that all preventive maintenance tasks should be finished within a 10% timeframe of the scheduled due date, considering the PM frequency.

For example, you want to run a PM program every month which averages 21 working days.

21 days * 0,1 = 2.1

Rounding it up, your team should be able to conduct a preventive maintenance program roughly in 2.5 days.

Now that you know the timing you can use the field service management software to schedule your preventive maintenance programs.

5.2. Consider field service management software

Regardless of the size of the company, keeping track of maintenance activities, the whereabouts of your technicians, and storing the data they collect on-site is a must not only for a successful PM program but also for the overall efficiency of your organization.

Field service management tools are digital solutions that allow managing mobile teams and enable smoother communication with their resources in the field.

You can register your maintenance activities, assign the technicians based on their availability, monitor their dispatch, arrival, and completion of the maintenance program, and much more.

As a result, you eliminate the possibility of losing your time due to the disorganization and lack of communication.

FSM solutions are a good tool to store all the needed data about your assets (the number, license, model, etc.). This is a crucial factor because, for a successful PM, you need to be aware of the type of equipment your technicians deal with. They also need to be able to update their progress and list the next tasks.

5.3. Empower your technicians with remote visual assistance

Although a preventive maintenance program aims to assess the state of the equipment, there is no guarantee that there will not be any malfunctions or that the state of the equipment is not worse. A technician can come prepared for one type of maintenance activity, but on-site discover that the situation is different or much more complex.

Such underprepared site visits can be eliminated with the help of remote visual support. Before sending a particular technician to the field, the team members on site can start a real-time video session and showcase the equipment that needs to be checked. The team in the office will be able to benefit from the 360° view and keep the recording of it even after the session ends.

If either of the collaborators is not available (there is a time zone difference or language constraints), the state of the machines can be reported via a video report. A technician records the video, adds annotations thanks to collaborative tools, and shares it with the team in the office. For situations where only a diagnostic is required, such asynchronous report can fully substiritute a time and energy-consuming trip on-site to perform the same thing.

Your FSM solution can be fully integrated with a remote visual assistance tool. It means that all video recordings will be enriching the created intervention/work order in the FSM allowing experts and technicians to keep track of the PM progress.

6. Conclusion

Preventive maintenance program is an essential step to prolong the lifecycle of your equipment, ensure employees’ safety, boost their confidence in the machines that they work with, and save costs that could have been associated with the replacement of the fully broken machines. By using the right digital tools, you can organize PM in the most efficient way and capitalize on the collected data.